|

|

|

Home Greenhouse Controller |

|

Low Cost Greenhouse Automation |

|

|

|

Tom Schmidt |

|

3/17/2015 |

Tom@tschmidt.com

|

In 2012 I designed a simple system to manage greenhouse ventilation and thermal storage. This paper describes the various features and the tradeoffs involved in implementing them. The brain of the system is a low cost programmable logic controller (PLC) that includes a web server. The system has been extremely successful. This revision documents several features I’ve added over the years. |

Table of Contents

Thermal Storage – Water Barrels

Integration of Greenhouse and Wood Heat Controller

Interface – Switch Conditioning

Greenhouse Basics

We have an 8 x 16 foot lean-to greenhouse attached to the south facing wall of the house. The lean-to design reduced cost and minimizes heat loss through the rear greenhouse wall. The greenhouse floor is at basement floor walk out level with a concrete frost wall extending 4 feet below and rising about 4 feet above the floor. The concrete wall is insulated with 2” of foam board and much of it is below ground level minimizing heat loss.

Greenhouse

structure is 2x6 and 2x4 pressure treated lumber with a channel routed to accept

8mm dual wall polycarbonate

panels. The inspiration for this construction technique came from a New

Yankee Workshop episode where they built a small standalone greenhouse. I

struggled with the problem of using fixed size glazing panels. Because this is

a lean-to design roof height is determined by the bottom of the first floor

windows. Standard sized panels did not fit in the available space. The

polycarbonate panels are ideal as they can be easily cut to size. Routing

channels in the framing lumber eliminated the cost of aluminum extrusions

normally used to mount the panels. Since the panels are retained in routed

channels the structure is not completely watertight so there are a few drips

during heavy rain/snow. This would be a problem if we were using it as a sun

room but not as a greenhouse. The leaks did however affect how the electrical

system was installed.

Greenhouse

structure is 2x6 and 2x4 pressure treated lumber with a channel routed to accept

8mm dual wall polycarbonate

panels. The inspiration for this construction technique came from a New

Yankee Workshop episode where they built a small standalone greenhouse. I

struggled with the problem of using fixed size glazing panels. Because this is

a lean-to design roof height is determined by the bottom of the first floor

windows. Standard sized panels did not fit in the available space. The

polycarbonate panels are ideal as they can be easily cut to size. Routing

channels in the framing lumber eliminated the cost of aluminum extrusions

normally used to mount the panels. Since the panels are retained in routed

channels the structure is not completely watertight so there are a few drips

during heavy rain/snow. This would be a problem if we were using it as a sun

room but not as a greenhouse. The leaks did however affect how the electrical

system was installed.

Ventilation is provided by three windows, one each on the east and west

wall and a central roof vent. I built the window frames out of pressure

treated lumber and used the polycarbonate panels for glazing. The windows are operated

by Bayliss

Autovent passive openers. A temperature

sensitive cylinder forces the window open as it heats up. A knurled knob at the

top adjusts opening temperature. The openers work great but simply opening

windows does not move enough air to maintain reasonable temperature during full

summer sun. Even with a shade cloth hung on the south face indoor temperature

is significantly higher than outdoor.

Ventilation is provided by three windows, one each on the east and west

wall and a central roof vent. I built the window frames out of pressure

treated lumber and used the polycarbonate panels for glazing. The windows are operated

by Bayliss

Autovent passive openers. A temperature

sensitive cylinder forces the window open as it heats up. A knurled knob at the

top adjusts opening temperature. The openers work great but simply opening

windows does not move enough air to maintain reasonable temperature during full

summer sun. Even with a shade cloth hung on the south face indoor temperature

is significantly higher than outdoor.

To keep the sidewall windows tightly closed I used 3 lb. cable tensioners to augment the Autovent openers. These are government surplus devices made by John Evan’s Sons Inc. I removed the Velcro and hooks and mounted them at the bottom of each window. The Autovent is able to lift 14 lbs. so works fine counteracting the tensioner. The roof window is heavy enough that gravity keeps it well sealed.

There are two entrance doors one from the basement and one on the west wall to the outside. The basement door has a dual pane fixed glass center section to let light into the basement. The exterior entrance door is a Larson midview storm door with a large movable screened opening to provide additional ventilation during the summer. During the winter we add a non-opening interior storm panel to minimize heat loss.

Due to the large amount of glazing greenhouse solar gain is high but so are loses. Without a large thermal mass temperature fluctuates rapidly, dropping at night and overheating during sunny days. This requires venting excess heat during the day and adding makeup heat at night. Adding thermal mass helps moderate temperature swing by absorbing heat during the day and releasing it at night. We opted for water barrel storage. Used 55 gallon polyethylene drums are cheap and water to fill them even cheaper. We use 6 55 gallon drums placed along the north wall. When I was searching for a local supplier was surprised to discover how many folks are selling them. Each barrel is painted black to maximize heat absorption. Ideally I should have used an additional 6 stacked on top but that would have consumed too much valuable space. Insufficient thermal storage means temperature fluctuation is higher than desired and without augmentation or opening the basement door greenhouse air temperate falls dangerously low during cold nights.

The floor of the greenhouse is filled with 4 feet of pea stone. Stone and masonry are great ways to store heat, the trick is to warm up the stone during the day and extract heat at night.

These limitations prompted me to embark on a project to automate greenhouse ventilation, energy storage and if needed to steal heat from the basement to maintain adequate temperature. The resulting controller is described in this paper.

Automation Wish List

1. Reduce summertime overheating and maintain adequate winter temperature.

2. Manage humidity during the winter when greenhouse is buttoned up.

3. If a problem occurs want to be notified without having to go to the greenhouse.

4. Override automatic functions in case the controller fails or we encounter unusual conditions.

5. Manage multiple indoor and outdoor temperature sensors.

6. Built in web server so greenhouse functions may be monitored remotely.

7. Local display of greenhouse air temperature.

8. The controller is on 24/7/365 so low power consumption is important.

9. Low price and cost of ownership.

Later when I built the 2nd generation wood heat controller added a 10th item to the list: communicate with the wood heat controller.

The design I ultimately came up with meets these requirements and I was able to add a few other features to boot. Being programmable allowed me to add features and tweak performance as needed.

Summer Ventilation

The passive

actuators work great to open and close the vents so I augment them with a roof

mounted exhaust fan. I used a dual fan assembly designed to cool server racks

mounted under the roof vent. In the picture you can see the Autovent

adjustment knob poking out behind the middle of the fan on the left. The fan is

designed to fit a 19” equipment rack, so it was easy to install within the

ceiling joists under the roof vent. The controller monitors greenhouse air temperate

to control the fan.

The passive

actuators work great to open and close the vents so I augment them with a roof

mounted exhaust fan. I used a dual fan assembly designed to cool server racks

mounted under the roof vent. In the picture you can see the Autovent

adjustment knob poking out behind the middle of the fan on the left. The fan is

designed to fit a 19” equipment rack, so it was easy to install within the

ceiling joists under the roof vent. The controller monitors greenhouse air temperate

to control the fan.

The fan assembly is plugged into a ceiling mounted receptacle. Because it is upside down I used a Twist-Lock receptacle to make sure the plug does not fall out.

Thermal Storage – Stone Floor

The floor

of the greenhouse consists of several feet of pea

stone. This represents a large thermal mass. A stone floor by itself is

not a very effective storage medium because not much heat is transferred to and

from the stone. To better utilize the mass I mounted a squirrel cage blower

near the roof, connected to a pair of 3” PVC DWV pipes to force air through two

flexible perforated pipes embedded in the stone. A centrifugal blower is a

good choice for this task because backpressure is high.

The floor

of the greenhouse consists of several feet of pea

stone. This represents a large thermal mass. A stone floor by itself is

not a very effective storage medium because not much heat is transferred to and

from the stone. To better utilize the mass I mounted a squirrel cage blower

near the roof, connected to a pair of 3” PVC DWV pipes to force air through two

flexible perforated pipes embedded in the stone. A centrifugal blower is a

good choice for this task because backpressure is high.

The controller monitors outside air temperate and turns the blower on when temperate falls below the set point. This way the blower does not run needlessly during warm weather. During the day warm air is blown into the stone heating it up reducing the need to vent excess heat. At night air blowing through the stone extracts heat to help maintain greenhouse air temperature.

Thermal Storage – Water Barrels

Six plastic

barrels are lined up against the north wall of the greenhouse. They are under

the boards on the left of the picture.

Six plastic

barrels are lined up against the north wall of the greenhouse. They are under

the boards on the left of the picture.

One of the temperature channels is used to monitor barrel water temperature. The water barrels are a passive thermal mass. The controller simply monitors water temperature to provide an idea of how much energy is being absorbed and released by the water.

Freeze Protection

If air

temperature cannot be maintained the controller turns on a fan that blows warm air

in from the basement. The fan assembly is identical to the ceiling exhaust fan;

however only a single fan is active the other is disconnected and blocked off.

The basement is heated so this infuses the greenhouse with 70ish degree air. A filter

keeps insects from entering the house.

If air

temperature cannot be maintained the controller turns on a fan that blows warm air

in from the basement. The fan assembly is identical to the ceiling exhaust fan;

however only a single fan is active the other is disconnected and blocked off.

The basement is heated so this infuses the greenhouse with 70ish degree air. A filter

keeps insects from entering the house.

During the summer a small door covers the opening to keep high temperate greenhouse air from infiltrating the basement. When greenhouse temperature drops below the set point and if the door is open the basement fan is turned on and the rock blower disabled. No reason to warm up the rock floor if we are trying to prevent inside air temperature from falling dangerously low.

The PLC monitors door state by reading a magnetically actuated switch. If the fan door is closed the basement fan is not turned on, the PLC sends out a warning email, and the rock blower is left running. If the door is closed the controller is unable to move warm air from the basement to the greenhouse. Leaving the rock fan on is the best fallback strategy to reduce the possibility of greenhouse freezing as warm air cannot be brought in from the basement. In addition to sending a warning email the basement fan status LED flashes indicating the door is closed.

Impending Freeze Warning

If these control strategies are unable to maintain adequate temperature the freeze warning light flashes and a notification email is sent.

Integration of Greenhouse and Wood Heat Controller

A freeze event is likely to occur in the wee dark hours of the morning when no one is logged into their computer so some other alert method is needed. The success of the greenhouse project encouraged me to design a second generation wood heat controller using another WebControl PLC. The wood heat controller has an audible alarm that is trigged during high temperature conditions so it was natural to use it for freeze notification. The 1-wire temperature sensors use three wires (power, ground and data). I wired the in house temperatures sensors with 4-wire cable so was able to use the 4th wire to communicate freeze warning to the wood heat controller. During a freeze event the controller pulls this line low activating an optocoupler in the wood heat controller. This turns the controller on, if it was off, and sounds the audible and visual alert.

House construction is extremely tight so running the fan to pump warm air into the greenhouse from the basement risks depressurizing the house. As long as the wood heat controller is active so is the fresh air fan bringing in outdoor make up air. To insure the wood heat controller is on when the greenhouse basement fan is running the greenhouse controller pulses the freeze line for 200ms when the fan is started and at 0 and 30 minutes past the hour if it is still on. This prevents the wood heat controller idle timer from turning it off. The wood heat controller ignores this short pulse and does not trigger the freeze warning.

Humidity Control

In the

initial design I neglected to consider the problem of excessive winter humidity.

With the greenhouse closed up humidity was 100% on some days causing mold to

grow on cold surfaces. To address the problem I added a small DC fan on the

East wall exhausting through a high quality metal dryer vent. The vent flapper

seals well preventing cold air from flowing back into the greenhouse. The PLC

includes a humidity sensor so I used that as primary fan control. The

algorithm disables the fan if outside temperature is high, no sense running the

fan if the vent windows are open. The fan is also disabled when inside

temperature is very low to reduce the rate of temperature fall and minimize how

much air needs to be brought in by the basement fan.

In the

initial design I neglected to consider the problem of excessive winter humidity.

With the greenhouse closed up humidity was 100% on some days causing mold to

grow on cold surfaces. To address the problem I added a small DC fan on the

East wall exhausting through a high quality metal dryer vent. The vent flapper

seals well preventing cold air from flowing back into the greenhouse. The PLC

includes a humidity sensor so I used that as primary fan control. The

algorithm disables the fan if outside temperature is high, no sense running the

fan if the vent windows are open. The fan is also disabled when inside

temperature is very low to reduce the rate of temperature fall and minimize how

much air needs to be brought in by the basement fan.

The fan is a 4-11/16” box fan powered from the 9V 1A supply used by the controller. The fan is rated for 12V but works fine at 9 volts, moving less air and drawing about 500ma. A FET is used to switch fan power.

Solar Batch Water Heater

The

greenhouse provided a convenient location to install a solar batch water

heater. Batch

heaters are simply water tanks heated directly by the sun. Normally they

are mounted in a sealed enclosure to maximize temperature gain. I did not have enough

room for an enclosure so mounted a couple of 30 gallon tanks, painted black, as

high as possible on the back wall of the greenhouse. This is less efficient

than putting them in an insulated box but any increase in water temperature

reduces summer hot water cost. Well water temperature varies between 45-55F

during the year. The electric water heater is set to 120 degrees. Just

reaching normal summer daytime air temperature of 80-90 degrees reduces energy

consumption by half. An advantage of this arrangement is during winter the

tanks provide an additional 60 gallons of thermal mass. It is interesting

monitoring the temperature of the batch heater tanks compared to the water

barrels during the winter. Being located near the roof and having a better

ratio of surface area to mass they are more effective than the 55 gallon drums at

capturing solar energy.

The

greenhouse provided a convenient location to install a solar batch water

heater. Batch

heaters are simply water tanks heated directly by the sun. Normally they

are mounted in a sealed enclosure to maximize temperature gain. I did not have enough

room for an enclosure so mounted a couple of 30 gallon tanks, painted black, as

high as possible on the back wall of the greenhouse. This is less efficient

than putting them in an insulated box but any increase in water temperature

reduces summer hot water cost. Well water temperature varies between 45-55F

during the year. The electric water heater is set to 120 degrees. Just

reaching normal summer daytime air temperature of 80-90 degrees reduces energy

consumption by half. An advantage of this arrangement is during winter the

tanks provide an additional 60 gallons of thermal mass. It is interesting

monitoring the temperature of the batch heater tanks compared to the water

barrels during the winter. Being located near the roof and having a better

ratio of surface area to mass they are more effective than the 55 gallon drums at

capturing solar energy.

Domestic hot water is produced by a 55 gallon electric water heater located in the basement. Many years ago I augmented it with heat from our wood stove. I plumbed an insulated storage tank into the water heater cold water feed and installed a heat exchanger in the stove plumbed to the preheat tank using a thermosiphon loop. Whenever the stove is in use it heats water in the preheat tank. As hot water is used the “cold” water being feed into the electric water heater is warmer than the water coming directly from the well thus saving electricity.

The solar batch heater acts as a second preheater. When hot water is used cold well water flows through the two greenhouse tanks. Temperature rise depends on sun intensity and water usage. The hot output is plumbed into the cold inlet of the wood stove preheat tank. Water from the wood stove preheat tank flows into the electric water heater to bring it up to the desired temperature. The wood stove tank can be bypassed in summer but it is pretty well insulated so being lazy I leave it in the system during the summer. I’ve documented the entire solar wood water heating system here.

I was concerned the extra plumbing and tanks would impact hot water flow but that has not been a problem.

PTRV

A Pressure

Temperature Relief Valve (PTRV) valve is plumbed into the “hot” tank. It dumps

water if the tank overheats or experiences excessive pressure. If water is

turned off to the greenhouse and the PTRV opens there is a risk of creating a partial

vacuum when it cools, potentially collapsing the tanks. A vacuum breaker is

installed on the pipe connecting the two tanks letting in air if the tanks are

depressurized.

A Pressure

Temperature Relief Valve (PTRV) valve is plumbed into the “hot” tank. It dumps

water if the tank overheats or experiences excessive pressure. If water is

turned off to the greenhouse and the PTRV opens there is a risk of creating a partial

vacuum when it cools, potentially collapsing the tanks. A vacuum breaker is

installed on the pipe connecting the two tanks letting in air if the tanks are

depressurized.

Cold Water Supply

Since I

needed to supply cold water to the batch heater it was a simple matter to extend

the cold water feed to a ¼ turn hose bib to water plants. To keep dirt from clogging

the stone we stretched filter fabric over the floor. This allows water to drain

but prevents dirt from getting into the rock.

Since I

needed to supply cold water to the batch heater it was a simple matter to extend

the cold water feed to a ¼ turn hose bib to water plants. To keep dirt from clogging

the stone we stretched filter fabric over the floor. This allows water to drain

but prevents dirt from getting into the rock.

Water Freeze Protection

During heavy ice and snow storms we can experience extended power outages lasting several days. Without electricity we lose well water and obviously the controller no longer functions. The system is designed to be easy to drain. Pipes slope toward drain valves and the tanks can be emptied. So far we have never had to drain the system. Even with a multiday power outage simply opening the basement door is enough to prevent the greenhouse from freezing. The plants are not happy but so far have not had any burst water pipes.

Three ball valves and two ¼ turn boiler drains, located in the basement, allow flexible control of the batch heater. Additional valves, located in the greenhouse, are used to drain the tanks.

· Mode 1 during summer the bypass valve is closed and the feed and return valves open. This causes water to flow through the greenhouse tanks as hot water is used.

· Mode 2 during winter the bypass valve is open as is the feed valve, the return valve is closed. This bypasses the batch tanks but leaves water to the greenhouse turned on to water plants.

· Mode 3 is used to drain the system. The bypass valve is open and feed and return valves closed. Two boiler drains allow air into the feed and return lies to the greenhouse so they can be purged. Valves in the greenhouse let air into the system and drain the tanks. The tanks are higher than basement plumbing so they need to be emptied first before letting air into the basement feed pipes or water will back up into the basement.

Lighting

The PLC

also does duty as the lighting controller. This allowed me to run low voltage

wiring to light switches located by each door. As a plus the web interface

allows lights to be turned on/off by remote control. Pretty cool, how many

greenhouse let you turn the lights on or off from a web page? The light switches

are SPDT momentary contact center off. The controller latches the last switch

state to turn lights on or off. Being monetary contact allows an unlimited

number of switches to be used in parallel.

The PLC

also does duty as the lighting controller. This allowed me to run low voltage

wiring to light switches located by each door. As a plus the web interface

allows lights to be turned on/off by remote control. Pretty cool, how many

greenhouse let you turn the lights on or off from a web page? The light switches

are SPDT momentary contact center off. The controller latches the last switch

state to turn lights on or off. Being monetary contact allows an unlimited

number of switches to be used in parallel.

Two Leviton CFL fixtures are mounted on the ridge beam between the two roof pitches. The fixtures are not waterproof so I was careful to mount them in the middle of the polycarbonate panels. For extra water protection cut circular section of automotive gasket material and placed it between the fixture and plastic electrical box. They are not intended as grow lights just to provide general purpose lighting.

Switched Receptacles

There are thee duplex receptacles on the south wall and two on the north. I split the outlet so the left side is constantly on and the right one is controlled by the PLC. This feature came in handy before I modified the controller to directly power the humidity fan. Implemented humidity code to control the outlets and plugged in a wall wart power supply to power the fan. At present the switched outlets are controlled by the manual override toggle switch on the controller panel.

Sensors

The controller supports multiple temperature sensors and a Honeywell solid state humidity sensor. In addition two of the digital inputs are used to monitor the external entry door and basement fan door.

Temperature

![]() The controller supports 8 Maxim/Dallas 1-wire DS18B20 temperature

sensors. 1-wire is a single line wired OR bidirectional communication

protocol. Each device is serialized allowing multiple sensors over only three

connections: 5 volts, ground and data. The sensors output temperature in

digital format and are powered from the PLC’s 5v output.

The controller supports 8 Maxim/Dallas 1-wire DS18B20 temperature

sensors. 1-wire is a single line wired OR bidirectional communication

protocol. Each device is serialized allowing multiple sensors over only three

connections: 5 volts, ground and data. The sensors output temperature in

digital format and are powered from the PLC’s 5v output.

Most of the sensors are mounted at the end of a flexible cable protected by a metal tip. The exception is the two ambient air sensors (controller and display). They are located in a small ventilated chassis on the South wall protected from direct sunlight. Currently 7 of the 8 channels are used:

1. Outside air

2. Inside air (a 2nd dedicated sensor drives the controller’s temperature display)

3. Water storage barrel

4. Not used

5. Well water at pressure tank

6. Solar batch preheater

7. Wood stove preheater

8. Electric water heater

With the exception of the solar batch heater the hot water temperature sensors are attached to the outside of the respective tank. With the batch heater I had an unused fitting so was able to locate the temperature sensor in direct contact with water. Temperature accuracy is affected by water usage. Temperature reading is more accurate if water is following through the pipe. If water has not been used for a while the reading is somewhere between tank internal temperature and ambient air temperate. This is especially pronounced with the electric water heater as the sensor is almost 4” away from the tank due to insulation.

Outside Air

The outside

air sensor is located on the North wall of the house. This required running a

cable from the greenhouse at the front to the north wall at the back. Mounting

was an issue as I needed the probe to measure outside air temperature but not

be easily damaged. The ideal location for highest accuracy is several feet

above the ground and away from the building. That was impractical so the sensor

is mounted only a couple of feet above grade in the wall itself.

The outside

air sensor is located on the North wall of the house. This required running a

cable from the greenhouse at the front to the north wall at the back. Mounting

was an issue as I needed the probe to measure outside air temperature but not

be easily damaged. The ideal location for highest accuracy is several feet

above the ground and away from the building. That was impractical so the sensor

is mounted only a couple of feet above grade in the wall itself.

To protect the sensor I used a small plastic pet food dish. The sensor is mounted through a hole in the center of the base. This allows air flow around the sensor while keeping it behind the edge of the building.

Greenhouse Air

I wanted to

display greenhouse temperate on the controller front panel. The PLC cannot

drive an external display; forcing me to use two 1-wire temperature sensors for

internal air temperature monitoring. One feeds the PLC the other the front

panel display. Using separate sensors is not ideal but the close proximity

insures they accurately track one another.

I wanted to

display greenhouse temperate on the controller front panel. The PLC cannot

drive an external display; forcing me to use two 1-wire temperature sensors for

internal air temperature monitoring. One feeds the PLC the other the front

panel display. Using separate sensors is not ideal but the close proximity

insures they accurately track one another.

The 1-wire protocol is open collector master slave. This allows both the PLC and display sensors to be powered by the controller’s 5 volt supply. Only the PLC and display data signals need to be kept separate and routed to the respective device.

The temperature sensors are located in a small ventilated box located on the south wall of the greenhouse below the glazing. This keeps them out of direct sunlight for more accurate readings. The humidity sensor is located in the same box as well as a terminal block in case we ever need to add a sensor at that location.

Water Barrel

To track water barrel temperature I connected a 1-wire sensor and dropped it into one of the drums through a hole in the bung cap.

End-to-End Domestic Hot Water

Four sensors are used to monitor the hot water system. These are not involved in greenhouse control they simply provide readings at various locations of the hot water system. Sensor 5 monitors well pressure tank, #6 greenhouse batch heater, #7 wood stove preheat tank, and #8 electric water heater.

Humidity

Humidity

The controller uses a Honeywell HIH-4000 sensor to measure relative humidity. This is an analog device powered from the PLC’s 5V supply. The humidity sensor is mounted in the same chassis used for the temperature sensors. Being analog I wanted to make sure accuracy was not affected by digital noise so I ran separate power, ground, and data.

Door Monitoring

Magnetic reed witches are used to monitor the status of the main entrance door and the basement fan door.

Web Interface

The WebControl web interface is pretty barebones but it gets the job done.

System Status page displays inputs and outputs as well as 8-varables used by the code. Being able to display values facilitates troubling shooting. VAR1 displays basement fan run time in seconds since the previous report. VAR 4 is high air temperate and VAR 5 low since the last report. The controller has another 8 variables (RAM) accessible to user code but they are not displayable.

The screenshot is a winter day when the wood stove is operating. Temperature sensor 1 measures outside air temperature. Sensor 2 is air temperature within the greenhouse and sensor 3 is the temperature of one of the water barrels. The last four sensors monitor various locations of the hot water supply. Sensor 5 is the well pressure tank; well water temperature varies little throughout the year. Sensor 6 is the hot outlet of the greenhouse solar batch water heater. Temperature sensor 7 is the wood stove thermosiphon storage tank and sensor 8 is the electric water heater. The water heater thermostat is set to 120 F. Because the sensor is attached to the hot water outlet pipe, rather than being immersed in water, the reading varies significantly depending if hot water has been used recently.

Email Alerts

No automation system is complete without alarm notification of dangerous or improper operating conditions. WebControl allows up to 8 preconfigured emails to be dispatched by user code.

Daily Status Email

The controller’s web interface is pretty limited and does not include logging capability. I added code to send out a morning and evening email. The body of the email includes digital input and output status and current temperate sensor and humidity sensor readings. Emails are generated at 6AM and 6PM. The firmware does not compensate for daylight savings time but in this case that is actually a plus since the report occurs at the same “Sun” time throughout the year.

Of particular utility is VAR1 that reports how many seconds the basement fan has run since the previous report, and VAR4 high and VAR5 low air temperature during the same period.

|

|

|

User Settings Report

The General

Setup screen is a convenient way to change set points without the need to

reload code.

The General

Setup screen is a convenient way to change set points without the need to

reload code.

v UROM1 sets ceiling fan temperature

v UROM2 sets rock fan outdoor temperature

v UROM3 sets basement fan temperature

v UROM4 sets humidity fan % relative humidity

To make setting more user friendly at power up and each time any of the UROMx settings are changed the parameter checker is invoked and an email sent indicating if values are correct and information about the correct range and units.

|

|

|

Freeze Warning

The point of having a greenhouse is to extend the growing season by keeping air temperature above freezing. If the water, rock storage and basement augmentation functions are not adequate to maintain air temperature the controller flashes a freeze warning LED on the front panel and sends a warning email. A pushbutton on the controller resets the alarm. If the freeze warning is reset while air temperature is still below the warning set point the LED is turned off for a couple of seconds and another freeze warning sequence begun.

The freeze warning event is communicated to the wood heat controller, activating an audible and visual alarm.

Basements Fan Door Warning

When the controller needs to turn on the basement fan it reads the state of the fan door switch. If the door is closed it flashes the basement fan status LED and sends a warning email.

Temperature Sensor Failure

If one or more temperature sensors fail a notification email is sent. It takes several seconds at boot time for the controller to initialize the temperate sensors. Testing is delayed when system powers up to eliminate spurious fault notification. The 1-wire bus is a wired OR open collector scheme. It is sensitive to noise ingress causing temporary failure of one or more sensors. To prevent unnecessary alerts sensor fault notification is debounced. When the controller reports a failed sensor a counter is set to 100. If the sensor is still bad after 100 passes through user code (about 5 seconds) the alert email is generated, if not the counter is reset.

Once an alert has been sent sensors must return to the OK state to reset the warning. That way only a single email is sent per failure event.

System Implementation

The controller is mounted on the east wall near the rear of the greenhouse. The temperate and humidity sensors are mounted on the south wall in a small ventilated enclosure. The Humidity control exhaust fan is mounted to the immediate right of the controller.

|

|

|

The controller is built into an 11” square electrical box. I installed an aluminum separator between line and low voltage compartment. The bottom section contains solid state relays to control AC loads. Initially I used SSRs to control all loads but ran into a problem with the CFL ceiling lights. The CFLs draw so little current the snubber circuit used to protect the SSR output passed enough current to cause the lights to occasionally flash. The solution was to replace the ceiling light SSR with an EMR. I mounted a small relay on a perf board cut to the same size as the SSR and wired a diode across the coil. The 7407 driver is able to control the relay directly so it made for a simple replacement. A flexible plastic shield covers the relays preventing accidental contact with mains voltage.

A 9V 1A DC “wall wart” style switching power supply powers the system. The supply plugs into a receptacle mounted on the divider protected by a fuse installed at the bottom of the cabinet.

The top portion has an 18-position terminal strip to connect low voltage field wiring; and an Ethernet jack connecting the controller to our home network.

The controller, interface PCB, override switches, status LEDs and temperature display are mounted on the hinged front panel. The humidity fan DC switching circuitry is mounted on small board attached to the fan toggle switch and LED. This minimizes interconnect wiring between front panel and logic board and kept high current fan load off the interface board.

WebControl PLC

WebControl PLC

The heart of the system is a low cost web server and programmable logic controller manufactured by CAI networks and available, like many of the other items used in this project, from eBay vendors.

The controller was primarily designed to monitor and control temperature in a data center environment, but its low cost and PLC capability made it ideal for my purpose.

WebControl Features

1. 8 1-wire temperature sensors inputs

2. Humidity sensor input.

3. 8 digital outputs

4. 8 digital inputs

5. UTP Ethernet port

6. Web server

7. Real Time Clock (RTC) synced via Network Time Protocol (NTP)

8. Low power

Interface PCB

I designed a simple interface board to provide external logic functions and ESD protection. The control panel has toggle switches to select how the various outputs are controlled. Each output except lighting can be set to: Off, On, or Auto. Normally switch overrides like this would be read by the controller and processed in software. However since there are only 8 inputs and 8 outputs I implemented the switch override function in hardwired logic.

I wanted the Freeze warning LED and Basement fan LED to flash when there is a problem. To eliminate the need to create time dependent PLC code I implemented the flash function in hardware. The controller has a status LED that flashes’ indicating the controller is alive. That signal is brought into the interface board to flash the appropriate LEDs.

The other function of the interface board is to protect the controller from ESD damage. I would much rather replace a SSI DIP TTL chip on the interface board then the entire controller. The protection scheme is pretty basic. Digital inputs are feed through a series resistor then to a pull-up. The output of the pull-up is clamped to Vcc and Ground by a pair of diodes. The 1-wire interface to the controller and display are bidirectional so I used the clamp diodes but not the series or pull-up resistor. The humidity sensor is run barefoot. Being an analog signal did not want to risk affecting accuracy. Outputs, except freeze, are not protected as they do not leave the chassis.

Temperature Display

I wanted to

display air temperature locally, but the controller does not have the ability

to drive a display. I purchased a self-contained LED thermometer

module. I chose a unit that uses the same 1-wire temperature sensor as the WebControl

and located it in the same box as the controller’s temperature and humidity

sensors. Using two sensors for the same reading is not ideal since tolerances

may cause measurement to may vary slightly but they are close enough for our

purposes. As a plus the LED provides a nice night light and confirmation the

controller is powered up.

I wanted to

display air temperature locally, but the controller does not have the ability

to drive a display. I purchased a self-contained LED thermometer

module. I chose a unit that uses the same 1-wire temperature sensor as the WebControl

and located it in the same box as the controller’s temperature and humidity

sensors. Using two sensors for the same reading is not ideal since tolerances

may cause measurement to may vary slightly but they are close enough for our

purposes. As a plus the LED provides a nice night light and confirmation the

controller is powered up.

DC Power

The 9V 1A wall wart style switching power supply is connected to the low voltage field wiring terminal strip. It plugs into a receptacle located on the chassis separator bracket. 9 volts is feed to the: PLC, SSRs, front panel LEDs, humidity fan, and the front panel temperature display. 5 volts, required by the sensors and interface logic, is provided by a linear regulator on the PLC. I added a heat sink to the regulator as a precaution for hot summer days. The PLC, interface PCB, SSRs, and LEDs draw 250 - 300ma from the 9 volt supply. The humidity fan draws 500ma. The switching supply is very efficient minimizing waste heat dumped into the enclosure.

AC Power

Greenhouse power

is supplied by a dedicated 20 Amp 120 volt circuit protected by a GFCI. This is

an important safety consideration given the close proximity of electricity and

water. I choose to use a GFCI circuit breaker rather than a GFCI receptacle

because I wanted to split each receptacle into a switched and unswitched side.

Greenhouse power

is supplied by a dedicated 20 Amp 120 volt circuit protected by a GFCI. This is

an important safety consideration given the close proximity of electricity and

water. I choose to use a GFCI circuit breaker rather than a GFCI receptacle

because I wanted to split each receptacle into a switched and unswitched side.

PVC conduit

protects exposed wiring on the east and south walls. Plastic conduit is

inexpensive, does not rust, provides mechanical and water protection of exposed

wiring. The north wall between basement and greenhouse is an insulated stud

wall. Wiring in the wall is NMC cable.

PVC conduit

protects exposed wiring on the east and south walls. Plastic conduit is

inexpensive, does not rust, provides mechanical and water protection of exposed

wiring. The north wall between basement and greenhouse is an insulated stud

wall. Wiring in the wall is NMC cable.

The National Electrical Code (NEC) requires protection when receptacles are used in web locations. With the exception of the twist-lock receptacle used to power the ceiling vent fan all outlets have a plastic protective cover.

Sensor Cabling

I used two Cat5e cables to interconnect the various sensors. The preferred topology for 1-wire devices is a daisy chain. A daisy chain minimizes the negative effects of reflections due to the unterminated nature of the bus. Temperature sensors are located both in the greenhouse and the house. Within the greenhouse I looped the sensor cable to all locations that require temperature sensors or other inputs then back to the controller. This allowed me to terminate both ends of the cable within the controller. This provides several benefits. I terminated both ends of greenhouse cable’s power and ground conductors effectively doubling the wire gauge, reducing voltage drop. Currently I’m only using 7 of the 8 loop cable conductors, having access to both ends of the cable means if I need to add additional inputs or outputs I can cut the loop to allow switches and sensor to feed one end or the other. The loop also provides some measure of fault tolerance.

Several temperature sensors are external to the greenhouse. The near end of the looped cable’s 1-wire temperature data lead is terminated at the PLC and the distal end is extended into the house along with power and ground, maintaining the optimum daisy chain configuration through both wire segments. Used a 19-gauge 4-wire cable I had laying around for the house cable to connect the outside air temp, well water temp, the wood stove preheat tank and electric water heater temp sensors. The 4th wire of the house cable allows the greenhouse to signal the wood heat controller about freeze events.

Maxim/Dallas 1-wire application notes provide recommendations to deal with signaling problems over long networks. Even though total cable length is about 35 meters the system operates flawlessly without needing any of those tweaks. By 1-wire standards this is a medium sized network.

I needed more than 8 conductors for greenhouse sensors so ran a second Cat5e cable from the controller to the sensor box. This cable provides point to point wiring for the display temperature sensor and the humidity senor.

Two Cat5e cables provide dual Ethernet LAN drops, only one of which is being used. These cables connect to the Ethernet patch panel within the house.

To-do List

I’m very pleased with the results but as typical with projects have no shortage of ideas for future modifications.

1) I plan to add another temperature sensor embedded into the stone floor to monitor its temperature.

2) Better status communication with wood heat controller. Currently the wood heat controller reports greenhouse controller health status based on the presence of 5V on the temp sensor lead. The firmware I’m now using on both systems enables IP based communication between the controllers. Taking advantage of this will improve heath reporting.

Conclusions

This has been a fun project and has greatly improved the performance of our greenhouse.

For anyone considering this type of project it is important to think about life cycle issues. The greenhouse structure and wiring have an extremely long life expectancy compared to the individual electronic modules. Think about how to handle a module failure 5 or 10 years down the road. Perhaps it is the packrat in me but given the inexpensive nature of the major components I’ve purchases spares that can be placed in service without mechanical, electrical, or software modification in the event of failure.

Appendix A Schematics

Chassis Wiring

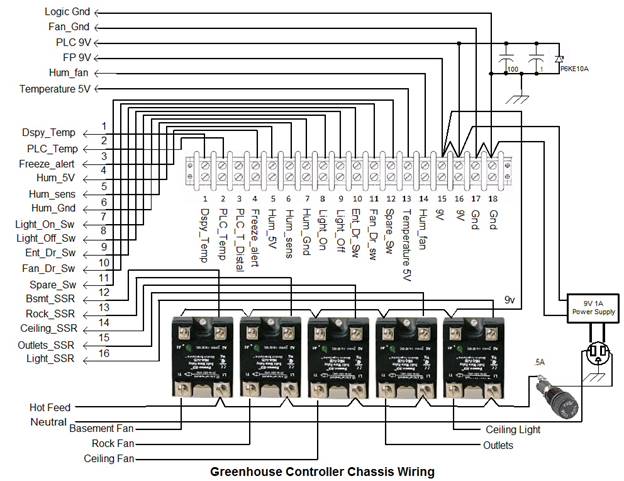

A 16-position DIP plug connects the interface board to sensor inputs and SSR DC control. Power and ground use 22 AWG wire to minimize voltage drop. Temperature 5V is obtained from the PLC and used to power the PLC and display temperature sensors. Power and ground for the humidity sensor is connected directly to the PLC to minimize effects of digital noise.

A .5 amp fuse limits fault current to the 9 volt power supply.

Front Panel Wiring

Front panel wiring picks up all the switches and LEDs in addition to the 1-wire temperature display module. The switching circuitry for the humidity fan is located on a small perf board mounted to the rear of the fan toggle switch and status LED. A FET low side switch is used to minimize fan voltage drop. Fan is rated for 12 volts but operates fine at 9, with obviously reduced air flow.

PLC Wiring

Two ribbon cables connect the PLC to the Interface board. A 16-pin header to header cable connects analog and digital inputs. Note: the PLC number’s the header sequentially. Conventional practice is to alternate pin numbers on ribbon cable headers so numbers are sequential across the cable. The other cable terminates at small barrier strips. The flash lead is soldered to the flashing health LED on the PLC.

5V for temp sensors is picked up directly from the PLC temperature header and routed to the field wiring terminal strip.

Interface – Logic

The Interface board is the central interconnect between the various portions of the controller and provides simple hardware logic and ESD protection. The PLC interface consists of a 16 and 20 pin header. Front panel wiring terminates to a 20-pin header providing lots of spares. And lastly a 16-pin DIP plug connects to the LV terminal board and SSR control.

Interface – Switch Conditioning

This page shows switch conditioning and termination of

unused spare gates.

Sensor Wiring

The loop cable originates at the controller and travels along all four greenhouse walls then returns to the controller. Loop wiring is routed through the light switches by each entrance door and connected to the magnetic door switches. A four conductor cable connects the 1-wire PLC temperature sensors in the house and provides freeze notification to the wood heat controller.

At various

locations I installed 4-postion terminal bocks (old style telephone 42A

junction blocks) to facilitate adding additional temperature sensors.

At various

locations I installed 4-postion terminal bocks (old style telephone 42A

junction blocks) to facilitate adding additional temperature sensors.

The point to point cable originates at the controller, runs across the south wall of the greenhouse and terminates at the ventilated chassis. The display temperature and PLC humidity sensor use this cable.

A small ventilated chassis is located on the south wall. It houses temperature sensors for the PLC and digital display, the humidity sensor and a 4-position terminal block to allow attachment of an additional cabled temperature sensor.

Appendix B PLC Configuration

Screenshots of various WebControl configuration pages.

Network Setup

This page selects DHCP or static IP configuration. It also allows setting the NetBIOS name. Web access to the controller can be unrestricted or require username/password login.

WebControl time can be set automatically via NTP or manually. The controller does not have a built in battery backed real time clock, time must be set each time controller is powered up or firmware sets default date/time. I run my own LAN based NTP time server so point the controller at that time server rather than one on the Internet.

Pressing “Send” updates network setting and reboots the PLC. This is a handy way to reset the PLC remotely even when not making any changes to network settings.

I/O Setup

Individual outputs can be configured to allow PLC control and direct control from a browser. In most cases PLC code will force the output to correct value even if web browser attempts to set or reset it but if not explicit control can be determine on this page. The active polarity of the outputs is set from this page.

Temperature Setup

1-wire devices are individually serialized. The controller detects temperature sensors at power up but they must be manually assigned to a particular sensor ID and units of measure specified.

Email Setup

Email can be set up to use any TCP/IP port but the unit does not support SSL. In addition to email this page also configures HTTP GETs (not used in this example).

Up to eight email messages may be configured and each can be sent to a different address. In addition to the subject line and message body the system automatically appends information from the System Status page.

I noticed a problem setting message body with some web browsers (Firefox, chrome, IE10) the second character of each line after the first is lost. Setting message body works fine using IE8.

Appendix C PLC code

Greenhouse Controller

T. Schmidt

*********** Change Log *********************

3/2/2015 Bypassed PLC series diode on terminal strip and disconnected 10Uf

cap on switched fan. Added heatsink to PLC 5V linear regulator.

2/3/2015 Changed VAR8 to RAM8 to free up VAR8 for debug. Freeze bit pulsing

at 0/30 minutes not working. Fixed bug, REALCOLD stops being called

once there is an increase in temp. Added call to FRZWINK from

ADDSECOND - this insures if fan is still running at 0/30 minutes

past the hour Freeze will get pulsed again.

1/29/2015 Added Freeze bit pulse at 0 & 30 minutes when basement fan running

to insure wood stove controller does not timeout during extreme

cold if fan runs longer than wood stove controller timeout.

1/23/2015 Added code to pulse Freeze bit for 200ms when basement fan started.

This wakes up wood stove controller to insure fresh air fan is on.

House is so tight GH basement fan tends to depressurize house.

1/6/2015 Fixed bug, rock fan not turned off when inside temp low and basement

fan running

12/30/2014 1) Changed UROM1-3 entry to degrees (from .1F) to make temp setting

more user friendly.

2) Reduced basement fan hysteresis to 1F (from 2F) to reduce fan run

time in cold weather. Fan will run more frequently but for shorter

period. This will also reduce high GH temp by 1F saving a few

house BTUs.

12/7/2014 Added debug email sent at power up. Looks like intermittent PS

problem. This is consistent with occasionally GH fail email from

Wood Stove cntrl.

Update 2/1/2015 - Occasional system reset caused by PS droop when

humidity fan turned on. Need to rework hardware to remove PLC power

diode to increase voltage to PLC and increase bulk capacitance

on 9V supply. Will add heatsink to 5V linear reg on PLC.

11/30/2014 Removed UROM bounds email inhibit on power up. Temp logger/basement

fan run time counter getting reset randomly again.

1/2/2014 Added basement fan run time logger. VAR1 reports number of seconds

basement fan on since last morning/evening email. Count is reset

when morning and evening email sent. Removed temperature logger

debug code. Fault no longer occurring - have no idea why.

11/25/2013 Changed VAR1 to VAR8 to see of possible FW bug resetting VAR1.

Manually set VAR1 to 1234 to detect reset.

11/22/2013 Low temp logger randomly being reset to current temp. Added debug

email when logger reset and changed powerup reg RAM8 to VAR3

to verify if powerup flag reset. Email logger shows that VAR1

used to manage email is being reset to 0 power up flag unaffected.

8/29/2013 Added validity check to freeze warning, must be low >3 sec.

7/7/2013 Added range check to UROM values, email sent after each value

change indicating in range or out of range.

indicating out of range or in range.

7/5/2013 1) Added power up init delay for temp sensor

2) Fixed bug if temp sensor bad at power up no email sent.

3) Fixed logger bug does not report min temp first cycle

after boot

4) Cleaned up humidity code

5) Replaced failed water drum temp sensor - T3

7/2/2013 Reinstalled controller

1) Using OP7 for humidity fan

2) Temp status fixed now testing all temp sensors

3) Changed logic state of freeze reset push button

7/1/2013 Modified hardware

1) Replaced freeze warning PB LS04 with 7407 to reuse inverter.

2) Added OP7 DC humidity fan control circuitry

3) Added freeze warning output to wood stove controller

4) Added TVS to 9v input

6/29/2013 WebControl PCB returned with updated firmware, 3.2.17d.

6/17/2013 Replaced light SSR with EMR to resolve problem with SSR

snubber causing CFLs to occasionally flash. Added gasket

to both ceiling CFLs to prevent water ingress.

3/21/2013 CAI Networks confirmed temp status bug. I submitted another

bug report developing wood heat controller. Same bug they

thought they fixed before. Confirmed temp status bits working

in FW version 3.2.17b.

1/5/2013 Email does not report min/max temperature correctly, always

reports current value. Unclear when email is sent relative to

user code request. Modified routine so temp reset to current

value is delayed Approx. 5 seconds after requesting email.

Looks like it takes about 1.5 seconds to send email. Assume

system code logs into SMTP server before creating email text

body.

Added Hi temp logging in addition to low temp.

Changed bad sensor debounce to minimize spurious email.

1/4/2013 Added low temperature logging to morning and evening email.

Lowest temp since last email reported in VAR5. Moved

12/5/2012 Added humidity control exhaust fan. Small DC 100 cfm muffin

fan exhausting through high quality dryer vent. Temporarily

used switched AC outlet channel. Need to update hardware in

summer with FET controlled DC Fan power to free up outlets

for other use.

10/30/2012 Installed

9/26/2012 Temp status does not report Temp sensors 7/8 correctly.

Submitted bug report to CAI Networks, stated 3.2.11 FW is a

year old and that bug is fixed in ver 3.2.12, current FW is

3.2.15. Cost $15 to upgrade. Choose not to upgrade at this

time.

6/25/2012 Code start

2/7/2012 Project start

*************** PCB Hardware/Firmware version ****************

Hardware: 2.2.2

Firmware: 3.2.17d

Customer loop executed every ~50ms (minimal test code) 65ms-ish (real code)

VAR and RAM initialized to 0 by system at power up

To reset PLC to power up state - update network settings (Send)

RAM location reset to 0 on code upload, VAR not affected

WebControl takes about 400ms to init I/O at power up

Per CAI Support Temp sensors take up to 2 sec to stabilize at power up

Email takes about 1.5 sec to send, no timeout if SMTP server does not respond

TTL inputs have 10k pulldown

Output buffers 10mA per output, 30mA total

A/D 10V full scale 10-bits

9V power consumption:

WebControl only 175ma (Live Ethernet serving web page)

WebControl + interface 220-250ma

Humidity fan: 500ma

***************** I/O Defs **********************

Analog Inputs

-------------

AIP1 - not used

AIP2 - not used

AIP3 - not used

Digital Inputs

--------------

IP1 - Light_on

IP2 - Light_off

IP3 - Ent_Dr_closed

IP4 - Bsmt_fan_dr_closed

IP5 - Spare_input

IP6 - /Freeze_pushbutton

IP7 - not used

IP8 - not used

Digital Outputs

---------------

OP1 - Rock_fan

OP2 - Ceiling_fan

OP3 - Outlets

OP4 - Basement_fan

OP5 - Light

OP6 - Freeze_warning

OP7 - Humidity_fan

OP8 - not used

Temperature Sensors

-------------------

T1 - Outside_air (house Northeast corner)

T2 - Inside_air (GH southwest corner)

T3 - Water_drum (north wall east of door)

T4 - not used

T5 - Well pressure tank

T6 - GH solar batch heater (east tank)

T7 - Wood stove water storage

T8 - Electric water heater

Temp Sensor status (1 = OK)

------------------

TS1

TS2

TS3

TS4

TS5

TS6

TS7

TS8

Humidity Sensor (GH southwest corner)

---------------

H1

Email message Identifiers

-------------------------

EM1 - Freeze Warning

EM2 - Bsmt fan door closed

EM3 - Sensor failure

EM4 - UROM out of normal range

EM5 - UROM in normal range

EM6 - Debug

EM7 - Morning daily status email (6AM)

EM8 - Evening daily status email (6PM)

Variables

--------

VAR1 - Basement fan runtime in seconds since last status email

VAR2 - Sum current UROM values. If match no email sent.

VAR3 - Powerup init flag

VAR4 - High Temp since last status email

VAR5 - Low Temp since last status email

VAR6 - Status email next time flag 6AM and 6PM

VAR7 - Bad Sensor state: 0=send email, 1-100 debounce counter, 101=email sent

VAR8 -

RAM

---

RAM1 - Scratch: Temp status, fan hysteresis

RAM2 - Basement fan door email once per occurrence, 1=email sent

RAM3 - Next second flag for basement fan runtime counter.

RAM4 -

RAM5 -

RAM6 -

RAM7 -

RAM8 - Email delay state: 0=set min/max temp to current, 1-1000=temp reset delay,

1001 email sent

Web constants

------------

UROM1 - Ceiling fan on, inside temp >75-95F (currently 85F)

UROM2 - Rock fan on, outside temp <35-60F (currently 42F)

UROM3 - Basement fan on, inside temp <35-60F (currently 44F

UROM4 - Humidity fan on, inside RH >60-90% (currently 75%)

**************************************************

GHINIT

Runs once at power up. Delay for temp sensors to stabile and sets VAR3 flag

RANGECHK

Tracks UROM values. Whenever value changes upper and lower bound for each is

tested and "in bound" or "out of bound" email sent. Runs at powerup and each

time UROMx value changed. Values are checked but FW does not override user

entered value.

NOTE: if one value is decreased by same amount another increased, sum does

not change so email is not sent.

LIGHT

Ceiling light control, latches last state of door pushbuttons

CEILING

Ceiling exhaust fan, on if inside air temp >UROM1

ROCK

Rock storage blower on when outside air temp <UROM2. Overridden if basement

fan on. No reason to attempt to store heat in rock floor if we are blowing

air in from the basement.

BSMT

Basement fan blows air in from basement if inside air temp is <UROM3. If fan

door is closed, LED blinks and email warning sent. VAR1 incremented each

second basement fan runs providing a cumulative total of run time. Count

is reset at morning and evening email. Accurate to +/- 1 second.

Pulses freeze bit for 200ms to wake up wood stove control each time fan is

started. This insures fresh air fan, connected to wood stove controller, is

running to prevent depressurization when basement air is pumped into greenhouse.

If fan is running at 0 and 30 minutes past the hour pulses freeze again to

make sure wood stove controller idle timer does not turn controller off.

FREEZE

If inside temp drops dangerously low, email sent and wood stove controller

activated to sound audible alert. Push button used to reset alarm. When

freeze is reset delay is invoked to cause LED to flash off momentarily if

reset while inside temp still too low.

HUMIDITY

If outside temp low enough and inside temp not too low and % humidity

exceeds URoM4 set point small exhaust fan on.

SENSOR

Monitors health status of 1-wire temp sensors, If sensor status bad for 100

passes through user code (VAR7) email sent. Reset if status returns to good.

EMSTATUS

Min/max temperature logged and basement fan run time. Status email sent

6AM and 6PM every day.

******************* Code *************************

START

TSTNE VAR3 1

CALLSUB GHINIT

CALLSUB RANGECHK

CALLSUB LIGHT

CALLSUB CEILING

TSTEQ OP4 0

CALLSUB ROCK

CALLSUB BSMT

CALLSUB FREEZE

CALLSUB HUMFAN

CALLSUB SENSOR

CALLSUB EMSTATUS

END

GHINIT:

SET VAR3 1

SET VAR7 100

DELAY 3000

RET

RANGECHK:

ADD UROM1 UROM2 RAM1

ADD UROM3 RAM1 RAM1

ADD UROM4 RAM1 RAM1

TSTEQ VAR2 RAM1

RET

SET VAR2 RAM1

TSTLT UROM1 75

GOTO BADUROM

TSTGT UROM1 95

GOTO BADUROM

TSTLT UROM2 35

GOTO BADUROM

TSTGT UROM2 60

GOTO BADUROM

TSTLT UROM3 35

GOTO BADUROM

TSTGT UROM3 60

GOTO BADUROM

TSTLT UROM4 60

GOTO BADUROM

TSTGT UROM4 90

GOTO BADUROM

EMAIL EM5

RET

BADUROM:

EMAIL EM4

RET

LIGHT:

TSTEQ IP1 1

SET OP5 1

TSTEQ IP2 1

SET OP5 0

RET

CEILING:

MUL UROM1 10 RAM1

TSTGE T2 RAM1

SET OP2 1

SUB RAM1 20 RAM1

TSTLE T2 RAM1

SET OP2 0

RET

ROCK:

MUL UROM2 10 RAM1

TSTLE T1 RAM1

SET OP1 1

ADD RAM1 20 RAM1

TSTGE T1 RAM1

SET OP1 0

RET

BSMT:

MUL UROM3 10 RAM1

TSTLE T2 RAM1

CALLSUB REALCOLD

TSTEQ OP4 1

CALLSUB ADDSECOND

ADD UROM3 1 RAM1

MUL RAM1 10 RAM1

TSTLT T2 RAM1

RET

SET OP4 0

SET RAM2 0

RET

REALCOLD:

TSTEQ IP4 1 OP1

NOP

TSTEQ IP4 0

CALLSUB FRZWINK

TSTEQ OP4 0

ADD CS 1 RAM3

TSTEQ IP4 0 OP4

RET

TSTEQ RAM2 0

EMAIL EM2

SET RAM2 1

RET

ADDSECOND:

CALLSUB FRZWINK

TSTNE CS RAM3

RET

INC VAR1

INC RAM3

TSTGE RAM3 60

SET RAM3 0

RET

FRZWINK:

TSTEQ OP6 1

RET

TSTEQ OP4 0

GOTO FRZWINK2

TSTEQ CM 0

GOTO FRZWINK1

TSTNE CM 30

RET

FRZWINK1:

TSTNE CS 0

RET

DELAY 800

FRZWINK2:

SET OP6 1

DELAY 200

SET OP6 0

RET

FREEZE:

TSTLE T2 360

CALLSUB NEWFREEZE

TSTEQ IP6 0

SET OP6 0

RET

NEWFREEZE:

TSTEQ OP6 1

RET

DELAY 3000

TSTGT T2 360

RET

SET OP6 1

EMAIL EM1

RET

HUMFAN:

TSTGE T1 700

GOTO HUMOFF

TSTEQ OP2 1

GOTO HUMOFF

ADD UROM3 5 RAM1

MUL RAM1 10 RAM1

TSTLE T2 RAM1

GOTO HUMOFF

SUB UROM4 2 RAM1

TSTLE H1 RAM1

GOTO HUMOFF

TSTGE H1 UROM4

SET OP7 1

RET

HUMOFF:

SET OP7 0

RET

SENSOR:

AND TS1 TS2 RAM1

AND TS3 RAM1 RAM1

AND TS5 RAM1 RAM1

AND TS6 RAM1 RAM1

AND TS7 RAM1 RAM1

AND TS8 RAM1 RAM1

BZ BADSENSOR

SET VAR7 100

RET

BADSENSOR:

TSTEQ VAR7 101

RET

DEC VAR7

TSTNE VAR7 0

RET

EMAIL EM3

SET VAR7 101

RET

EMSTATUS:

TSTEQ RAM8 0

GOTO NEWMINMAX

TSTEQ RAM8 1001

GOTO LOGGER

DEC RAM8

RET

NEWMINMAX:

SET RAM8 1001

SET VAR4 T2

SET VAR5 T2

SET VAR1 0

RET

LOGGER:

TSTGT T2 VAR4

SET VAR4 T2

TSTLT T2 VAR5

SET VAR5 T2

TSTEQ CH 6

GOTO MORNMAIL

TSTEQ CH 18

GOTO EVENMAIL

RET

MORNMAIL:

TSTEQ VAR6 18

RET

EMAIL EM7

SET VAR6 18

SET RAM8 1000

RET

EVENMAIL:

TSTEQ VAR6 6

RET

EMAIL EM8

SET VAR6 6

SET RAM8 1000

RET

******************* End **************************