|

Schmidt Consulting |

|

Inline DC Power Monitor |

|

|

|

|

|

Tom Schmidt |

|

6/26/2020 |

http://www.tschmidt.com/

|

I wanted an easy way to monitor wall warts and the devices they power. This is a low cost device that can be inserted in line on most externally powered devices. |

Overview

A lot of the stuff I work on is powered by DC wall wart power supplies connected via barrel jacks. These tend to use a narrow range of DC voltages: typically 5V, 9V or 12V. Current is normally under 3A. In the olden days a lot of wall warts were simply small transformers outputting AC but today almost all are switch mode DC power supplies.

The main reasons I built the adapter is most of our networking gear is powered by a DIY UPS that outputs DC, replacing the supplied wall warts. 12V devices run barefoot from a 12V SLA battery and devices that require a lower voltage are powered via a buck converter. When installing a new device I want to see how sensitive it is to input voltage to determine if it will be happy powered by the UPS and to observe typical current draw to estimate run time impact.

The Adapter

The heart of the device is a low cost DC volt/amp panel meter I purchased on eBay for under $3US. Power enters from the left, via a 5.5/2.1mm barrel jack or a set of dual banana jacks. The banana jacks are handy when powering from a lab supply to verify voltage sensitivity. Output is via a 5.5/2.1mm barrel plug or a set of dual banana jacks. 5.5/2.1 is the most common size of barrel jack but as you can see from the picture there is a huge variety of sizes. I found a nifty set of adapters, also on eBay, which takes a 5.5/2.1 plug and convert it to other sizes. On the input the barrel jack size problem is not as important. I have a collection of 5V, 9V and 12V supplies with 5.5/2.1mm plugs. Not shown in the picture is an adapter that takes a 5.5/2.5mm plug and converts it to 5.5/2.1mm. That is probably the second most common barrel jack size. I’ve also found barrel jack to USB adapters but as of yet have not purchased any as I previously built a dedicated USB power monitor/dummy load.

The most common polarity for barrel jacks is negative outer shell with center pin positive. The switch on the right side allows polarity to be reversed. I had a nice locking toggle switch in my junk box that I used to minimize the chance I’d fat finger polarity letting out the magic smoke.

The switch on the left simply turns load power on/off.

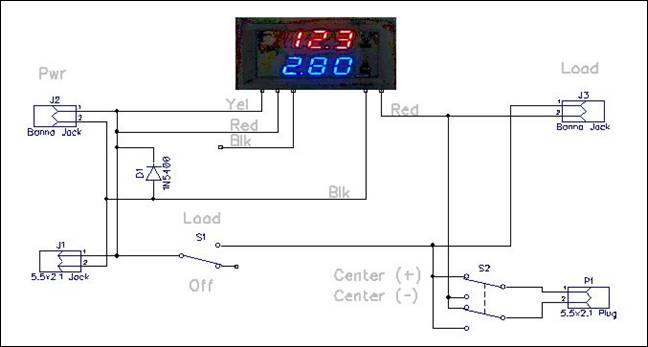

Schematic

Wiring is pretty simple. I stuck a high current diode across the input. If polarity to the power monitor is reversed the diode becomes forwarded biased shorting out the supply.

Low Side Current Sensing Issue

The panel meter senses current on the low side power rail. This is not a problem as long and the power supply and load are not connected to anything else. However if there are parallel low side paths they shunt the current sensing element causing a false low reading. This is normally not a problem as the wall wart low side is floating and power is only connected to a single load, but it is something to keep in mind.

Sizing Barrel Jacks

While perusing the internet I came across several clever ways to determine barrel plug center dimension. Outside dimension is easy to measure if you have a set of calipers or a micrometer. A low tech method to determine the inner pin dimension is to insert a round toothpick into the plug. Most round toothpicks are about 2.1mm in diameter so will fit snugly a 5.5/2.1MM plug but fall out of a 5.5/2.5mm one. A more exacting method is to insert a small drill bit to determine internal size.